EngSplainin’

a pivot click torque wrench.

So

you think you can reef on a one of these anywhere you like, good luck with

that!

Your

greasy mitt has to be on the handle IN THE RIGHT PLACE and here is why…

In

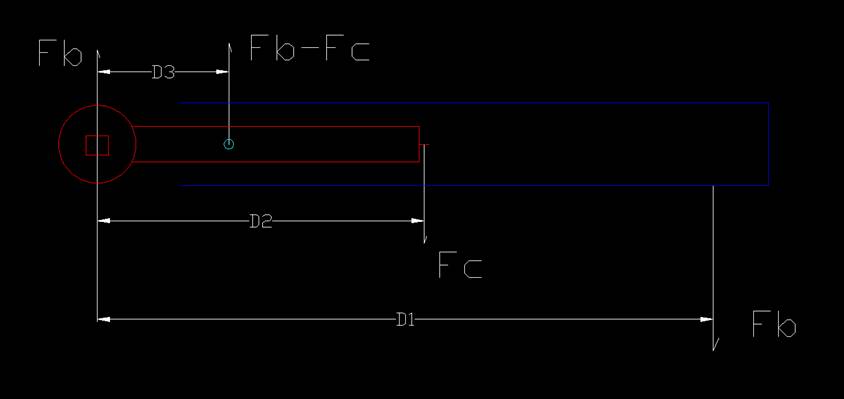

the depiction below:

·

Fb

= the Bogun force (your greasy mitt and Fosters powered muscle),

·

Fc

= the “click” force of your calibrated torque wrench (constant),

·

D1=

distance from bolt center to your mitt,

·

D2

= distance from pivot to clicker,

·

D3

= distance from pivot to bolt center,

·

Mega

= a hell of a lot,

·

SFA

= Sweet F All or bugger all.

Assumptions:

1. Fc is calibrated and is

CONSTANT. It cannot change and gives the

same force every time it is actuated within variation of the mechanism (SFA),

2. STP standard temperature and

pressure,

3. Standard gravity,

4. Standard laws of physics,

5. Above room temperature IQ, if you

can read this you pass,

6. ONLY D1 is changed in any testing as

an input.

Some

of the forces detailed are reaction some are action this is very simplified but

I hope will get the point across as to where this “magic” torque is coming

from. It is the reaction on the pin

equal to Fb - Fc

Now

for the splainin’:

Bolt

torque is (D1 x Fb) + ((Fb-Fc) x D3). If

your mitt is in the right place it works.

If

D1 gets VERY big, it affects the force needed and Fb becomes SFA to click the

torque wrench but the second part of the torque formula gets very small and the

((Fb-Fc) x D3) component of APPLIED TOTAL Torque is low so if you put a cheater

bar on the torque wrench you will UNDER torque the fastener.

Conversely

if you “choke up” and D1 gets small, Fb becomes a Megaforce,

you will be blowing chunks to get that wrench to click. ((Fb-Fc) x D3) becomes MUCH bigger and you

will OVER torque the fastener.

The

point that is missed is the fastener has TWO applied torques on these pin torch

wrenches and the D1 length will directly affect the amount of force, and

thereby magnitude of second torque that is applied to the fastener.

Please

apply safe torques to your member and appropriate harmonic frequencies to ming moles.

There

is even a Torque Wrench SIMULATOR.

Download

the Excel sheet, see the formulas, prove to yourself it is a problem to choke

up (over-torque) or cheater bar (under-torque).